klue

-

Posts

493 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

supertorial

Classifieds

Posts posted by klue

-

-

i want to buy some jeans

If you live in new england, the best way to get in the jeans is to come by the shop. Otherwise send some measurements and some loot electronically and well send the jeans. 225 for 13 oz. Cone mills denim, 275 for 16 oz. Japanese slub denim.

0 -

leather fur lined hat

0

0 -

how can I get an apron?

send me a check for $35 or $60 depending what style you want, or paypal [email protected], let me know your address, and you'll receive it in no time

0 -

womens jeans look sweet klue. make some for sarah please.

what size is she?

0 -

:eek:

The combs on the pair the guy with the yellow shirt is wearing are insane.thats the 24 oz. denim

0 -

-

-

I think denim contest can be compared to skiing under the lift line

0 -

Details of new small girls Jean proto series

Custom Ct state seal white enamel over flat black tack buttons. made by Waterbury button, one of the oldest button manufacturer in the country. Made in Cheshire Ct. The grapevines represent the three original settlements of Windsor, Hartord, and Whethersfield. The motto on the bottom translates to " he who transplanted, sustained" this is one of the principals of Hartford denim philosophy

Cone mills 13 oz. Indigo selvage

0

0 -

The jamaicans love this patch

0

0 -

-

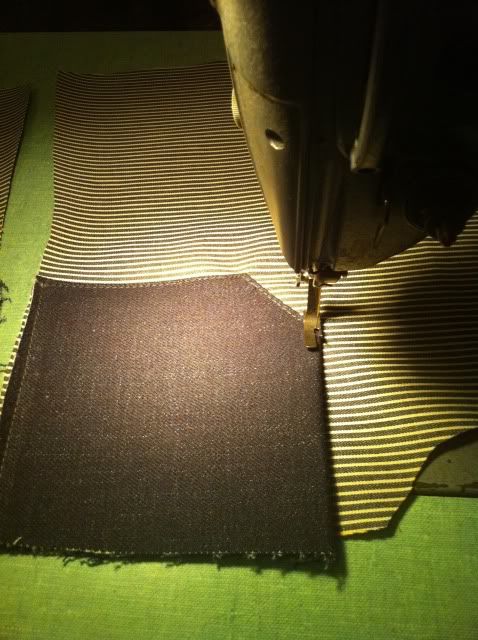

Today we started off finishing a run of aprons and beginning the construction of some all young womens jeans.

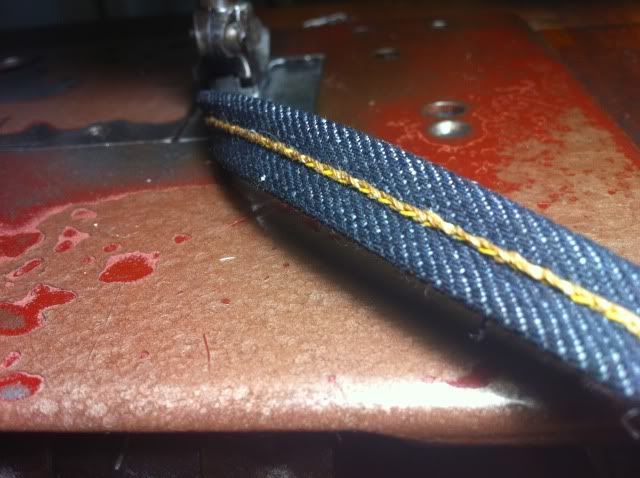

The new old singer overlock 246-45 making girls flys

And some bonus chainstitcher shots

0

0 -

I started with a pair of a.p.c.'s about eight years ago. I soon thereafter found superdenim, and within two years I managed to spend $1000 I didn't really have on flathead, skull, fullcount, and sugarcane. Meanwhile I began to b

Deconstruct and reconstruct. I began building jeans from duck from joannes fabrics. I then found premium denim and began making jeans. The whole time I am studying arboriculture and landscaping at Penn state. Meanwhile Marshall is hand sewing leather in Ct, and dave is building 48 sided round riding pens all thoughout the east coast. I left school and came back home. Marshal and Dave were both around. We all went to highschool together. I shared my skills I developed and they shared theirs. We started the company in the summer working our of our parents garages. Within six months we have relocated 6 times and we are now living in downtown hartford makin jeans full-time.

It's an exciting time for the development of our company and I willbe sharing much of those developments on this thread.

1

1 -

Hartford denim 3 months no wash, cone mills 13 oz.

0

0 -

So then I reproed my big smith Hartford denim style

1

1 -

0

0 -

All the same denim, different lighting

0 -

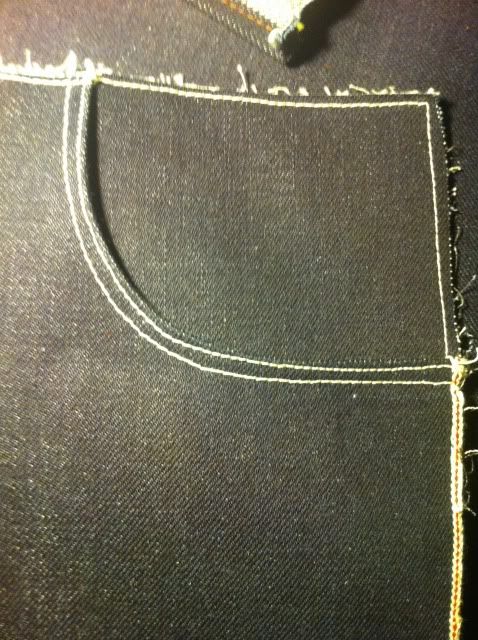

Front pocket topstitch

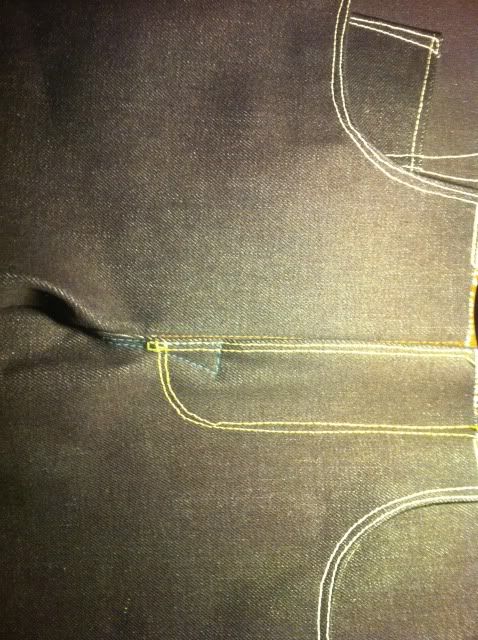

left front panel, fly zone

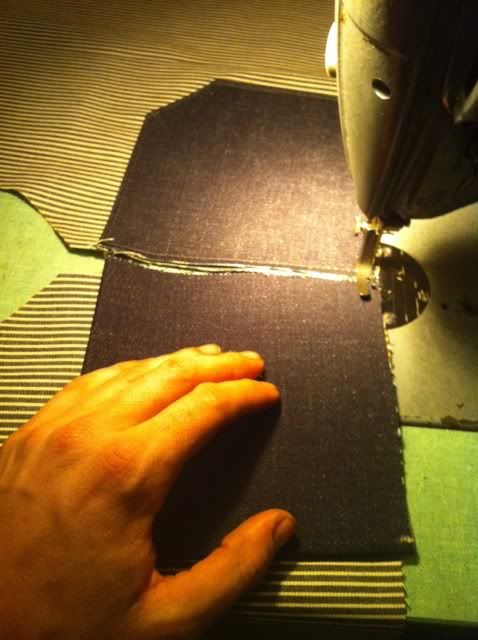

sewing buttonholes on left panel

Right side fly piece

Back panels joined

Front together

0

0 -

Rivet, burr, and old ice pick

The ice pick breaks

The Leather awl is used

From the back

It needs help getting through

One the copper peeks, it's ready for the washer

Pound the washer down

Cut the rivet and peen it over

0

0 -

Cut excess pocketing

Flip, iron, and sew

Notice the skipped stitch.

Fixed on the second pass

Tomorrow I will use titanium needle to try and minimise the skipped stitches.

Rivets coming to the back sides as well

0

0 -

Attaching denim to front pockets. One of the simpler jobs on the jeans. This is for a size 34.

Hemming the fifth pocket

Ride it straight into the next stitch for no waste

Putting pocket on

Returning for a skipped stitch

All tightened up

0

0 -

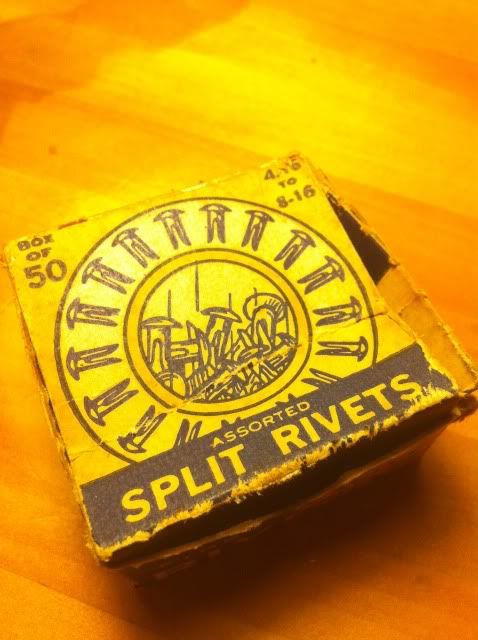

Does anyone know about these?

0

0 -

Right now I am in the business of custom orders for a small run of jeans rather than single pairs. I do have a size 32 and 2 x 34s that i will be exploring and refining my 24 oz. Construction techniques. I will sell these to individuals. Pm if interested.

0 -

Overall the armscye seam was the hardest to do. Everything else not too hard. The collar was a bit tricky, but not too bad, but pulling off a hand-felled armscye was a bit dicey.

What machine did you use for this?

0

Hartford denim company

in superdenim

Posted

an old high school classmate came to us to film his latest music video

http://www.youtube.com/watch?v=Y73w3mXKaXc