-

Posts

1628 -

Joined

-

Last visited

-

Days Won

8

rodeo bill last won the day on September 18 2023

rodeo bill had the most liked content!

Reputation

178204 you are so fabulousProfile Information

-

gender

not telling

-

location:

out West

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

^thanks, I know those two are special ones. I'd much rather sell here- they've been in a box for a decade, they deserve to be enjoyed!

-

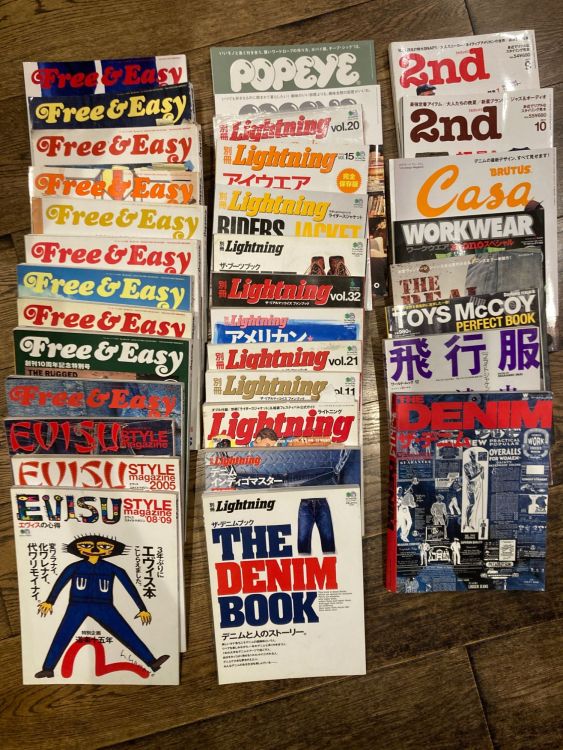

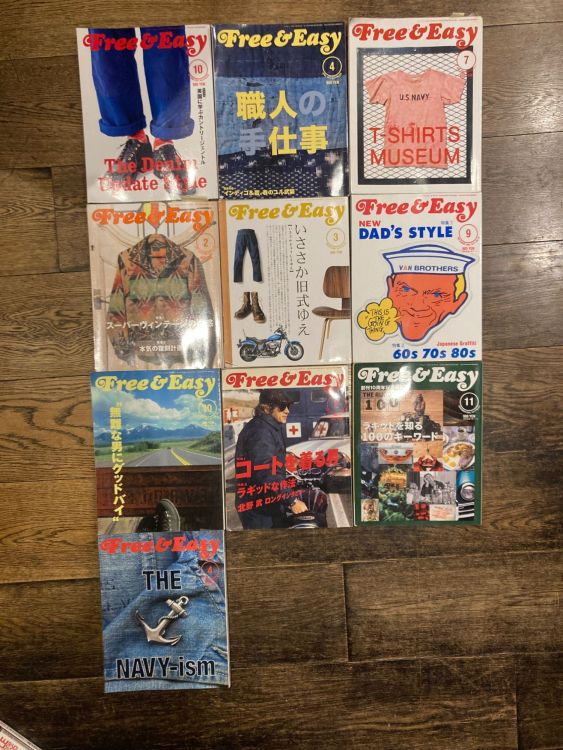

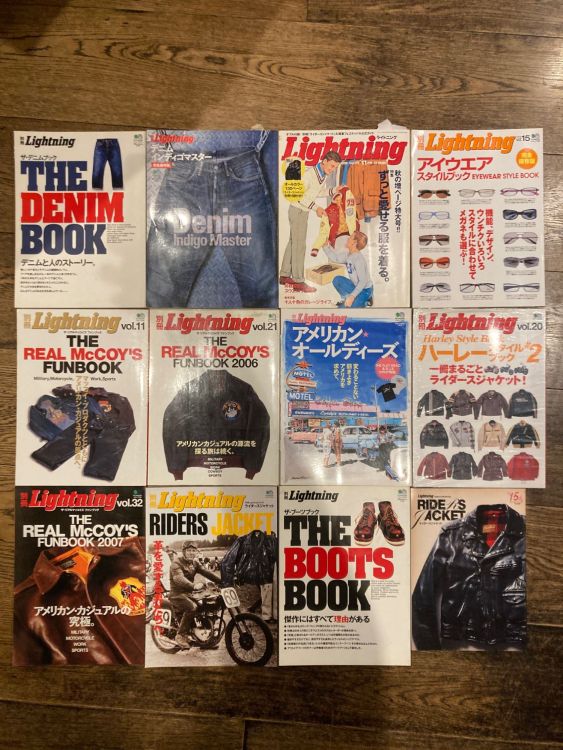

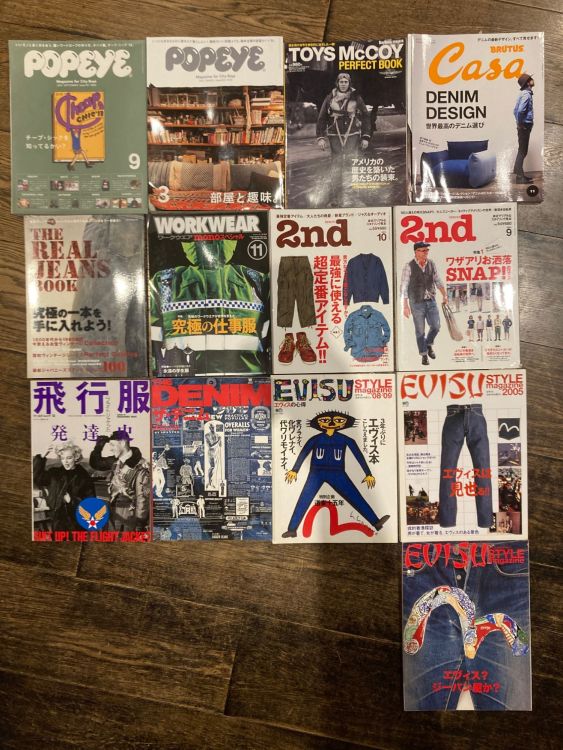

SOLD April 18th Having a clearout of magazines: Free & Easy, Lightning, McCoys, Evisu, Popeye, 2nd etc. I have these on eBay for £100 starting price for the lot, but open to offers here, I'd like them to go to a good home. Some edge turndowns etc but basically as new. Please let me know if any questions.

- 1057 replies

-

10

-

The Ry Cooder soundtrack stands up very well as an album, I think, and the dialogue snippets really hold it together.

-

lovely to see all these jeans @merzbot @irual @bartlebyyphonics, fading twisting and repairs all looking great. Really good to see a pair of hadal jeans wearing in, too- please keep us posted. Here are my 12oz Cross Weave 136s. I get such a kick out of seeing the right-hand twist on a left hand twill fabric cut sideways 🙂

-

Indeed! I really like this fabric too, and it's particularly interesting how it takes the darker dyes, which make the colour variation much more subtle. I'll have one more variation in this fabric over the next few weeks, but I'm afraid none going to EU stockist this time. Here are some closeups of the 'rough' logwood and hadal purple dyed versions. The rough logwood was a test using a mix of old more coarsely ground logwood powder, it didn't dye as evenly as regular logwood (particularly the newest batch of black logwood which came out beautifully dark and clean) but I think works really well on this fabric, which is slightly coarser and heavier, and in this style, which works best as an overshirt/light jacket.

-

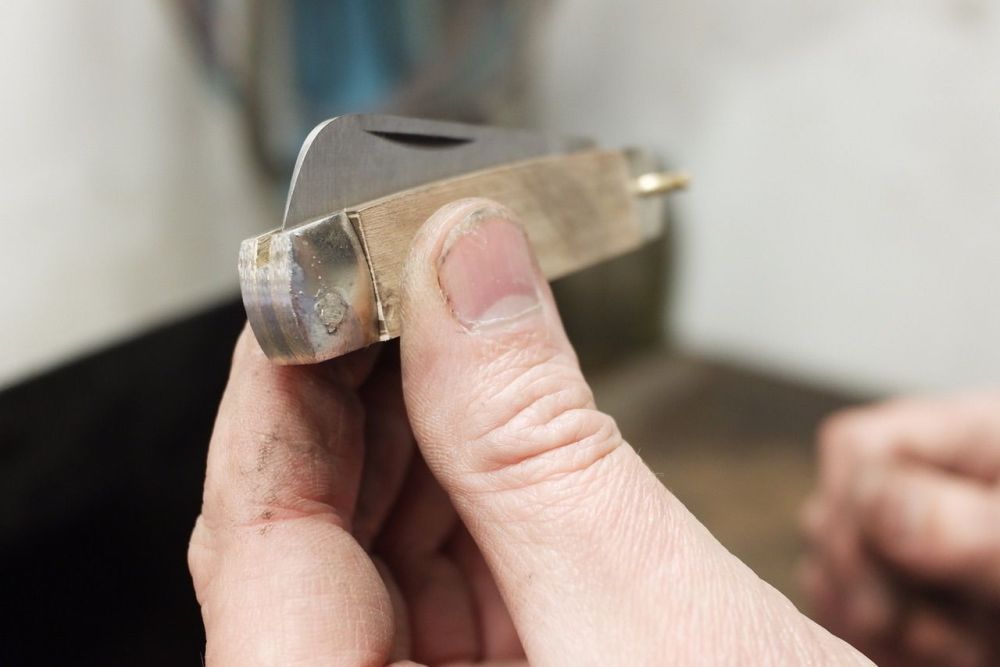

A new project: penknives, made in England on a brass skeleton with nickel bolsters at each end, a carbon steel blade and scales cut from pear wood from a tree in our garden. Here are some pictures of the making process, at a three-person factory. Here's the timber for the scales (sides of the knife handle), left over from some work done on a ~250 year old pear tree in our garden, that was splitting. The timber was seasoned over four years in a dry woodshed, and then inside for the last year, to stabilise it. The first thing to do is to cut it down to size, on a band saw, first into a thin flat slice, and then into individual bars for the scales: thin brass sheet skeleton pieces are then laid on top, and the scales are drilled through the plate, in the places where the rivets will be: A bolster is a metal piece at the junction between the blade an the handle of a knife. It strengthens the joint and smoothes the shape between the two materials. In kitchen knives it also covers the end grain of wooden scales, which could be unhygienic. In a pocket knife, I was a bit concerned about having sharp corners of wood exposed to knocks, so this knife has an additional bolster at the hilt end. These bolsters are pressed out of nickel, and are drilled through the skeleton as well, on either end of the pear wood scales, keeping everything lined up nice and tightly: here's the matching pair all lined up but not yet fastened together: The bolsters are now soldered in place, to hold everything properly aligned before it's all riveted: Next, the back spring is fitted. Pressed out of steel plate, it's drilled out and profiled to match the handle shape: the blade is a deadstock British Army pattern, made in Sheffield of a mid carbon content steel. Low carbon tarnishes less (stainless), but is relatively soft and doesn't hold a sharp edge well. Too high a carbon content and the blade can be brittle- it's very hard and doesn't blunten, but is difficult to sharpen and not really suitable for a general-purpose pocket knife like this: Here's the knife made up on long rivet pins, not yet fixed in place: but for now, the blade is taken back out, and a piece of steel the same thickness is inserted between the scales to stop anything bending, then the bolster and spring rivets are hammered into place the ends and sides of the scales now get the first, rough, sanding to shape them to the brass skeleton now the blade is slotted into place, and another rivet wire is fitted and snipped off The back of the knife is ground down so that it will all line up flat once it's riveted. At this point the blade hasn't been sharpened, so the following processes aren't quite as risky as they look! The snap of the spring can now be tested and the blade shape adjusted if necessary Now the blade rivet is hammered into place, and the scales are rounded off to match the shape of the nickel bolsters finally, the blade is factory-sharpened on a grindstone and the handle is printed, then it's finished! most knife handles would be sealed, but I preferred to leave the wood with just a light oiling- this way it will darken and take on indigo from jeans pockets, over time. I hope this has been interesting! It's been lovely for me to learn about a new craft, and fun to do a post about it- it's been a while, as most of the production techniques for clothing have been covered earlier in the thread. I've had my own knife a couple of months now, and it's looking lovely. Updates as it evolves.

-

lovely comparison photo! your 132s are certainly going to fit quite differently from the 129s. The denim is exactly the same spec and mill, although it will be from different batches. I expect the difference is in the washing that's gone into your 129s- both woad and Achilles' Heel are dyed relatively cool and gently rinsed, so they shrink a bit further with subsequent washing. When garments shrink the yarn gets denser as the fibres contract, and the weight/area increases which also makes the fabric feel harder. My guess is that the new jeans feel how the old jeans did, and they will feel how the old jeans do now after a few years. Alternatively there certainly could be some variation in the fabric. Details have evolved somewhat over the years- I note that your 129 side belt loops are the 'transition' length (!). Originally the side belt loops were extended and sewn through the yoke seam, however this caused a lot of broken needles, going though a lined belt loop and 4 thicknesses of denim in the seam, which also risked damaging the seam itself. For a while the side belt loops were longer than the front and back ones, sewn though a single thickness of denim, but more recently the belt loops have been matching lengths, and set closer to the side seam, to give more support to a belt at the sides, where it's most needed. Snob's thumb pockets haven't intentionally changed, although the side pocket mouth will be a bit bigger in your upsized 132s than in your 129s, which will make the thumb pocket look proportionally smaller. Again, though, it is possible that there's a bit of natural variation over the years between the two versions. Looking forward to see how the fit and dye works out for you on your 132s- Please do let us know.

-

Michael Stipe in something black overdyed, 1994, with Courtney Love. (Photo from a NYT long read about him, never been a fan but really interesting guy)

-

a nice exchange with a regular customer and friend of the brand over the last week, which I thought might be enjoyed here, particularly by @julian-wolf(apologies if I misunderstand your profession Julian) I gifted a pair of the chlorophyll-dyed socks to a biologist friend who's planning to look at them with a state of the art microscope he built out here in SF — apparently chlorophyll (in it's natural state, at least) will brightly fluoresce when hit with a certain color of laser light. - They fluoresce! He's testing against some laser safety glasses here that filter out 405 nm laser being used — because they fluoresce, you still see some light coming through the safety glasses. Not a dramatic effect, but definitely there.

-

once you've gone Profi Birki you'll never go back. Neoprene footbed for service/care industries, and a higher back than Super Birkis so they don't slip off.

-

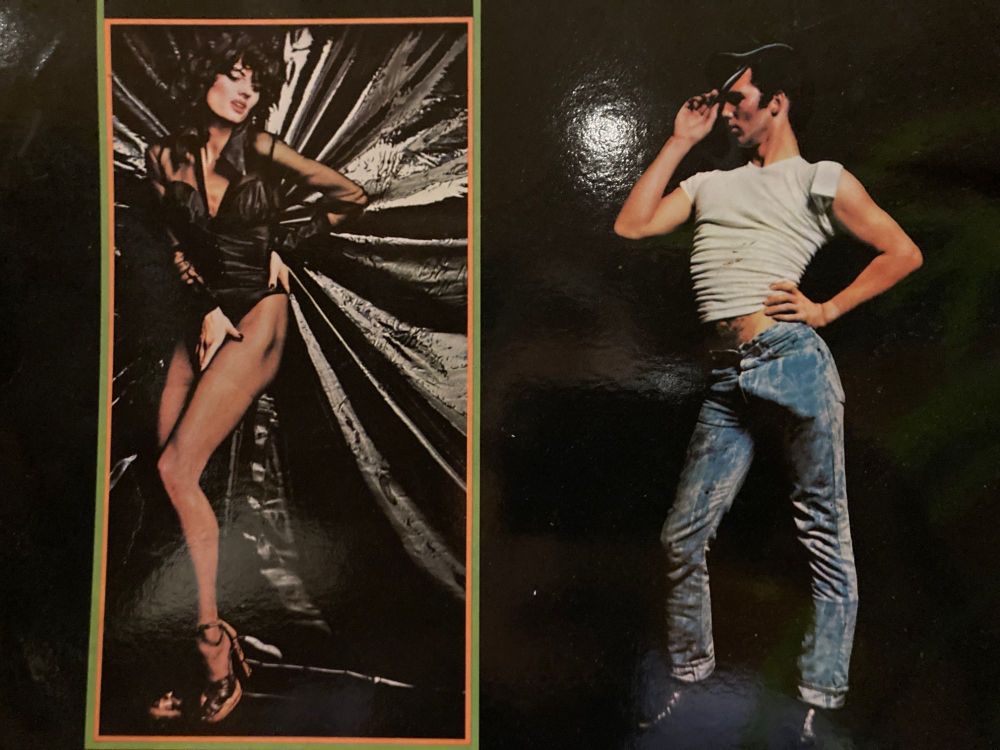

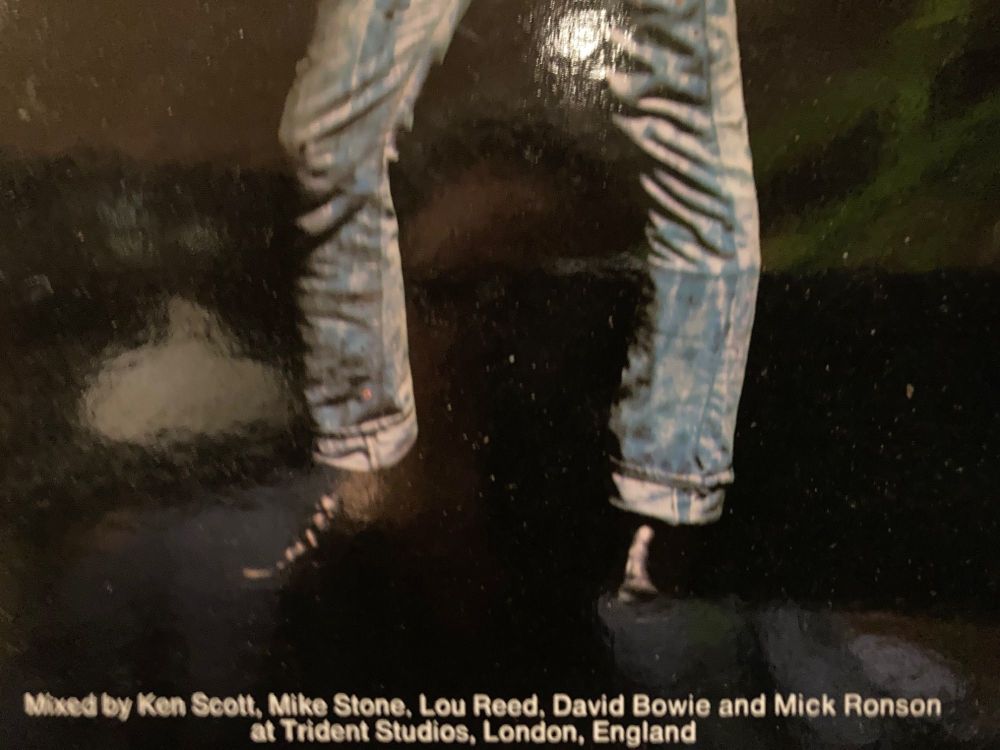

I just got this on vinyl (Lou Reed’s Transformer), an old favourite but I’d never seen the back image in large format- red line selvage, looks like Pinto wash!

- 1288 replies

-

10

-

Aha- yes I only made the indigo cardigan in the wool pattern, with a twist (which is the one Desolate has, I think. The only no-twist indigo cardigan is the linen-indigo, where the linen helps to stabilise the fabric. It's a lovely style, please do email me if you'd like more info. @desolate yes please it'd be great to see your cardigan! Lovely story about the desk. Do you have a clock to match? I always liked the animal ones (especially the fish)

-

@desolatethese are fantastic! lovely to see the satchel again- it's worn in beautifully, as have the boots and wallet. Great roll-top desk, too. @JDelageyou don't mean the 747 indigo cotton and natural linen rower's cardigan do you? In which case I have it in stock. I can't think of any other indigo cardigans other than this and the wool pattern cardigan, although I may be forgetting something!

-

Here we are at 9 months, and finally in stock! New type 122 Pleat Back Jeans, based on 132s but with pleats into the waistband instead of a yoke, and no back pockets: I'll sort out some fit pics soon, but I've really been enjoying wearing them- I rarely use the back pockets of jeans which have them, and I've found the lack of yoke and pocket bulk to be really comfortable to wear.

-

Obviously can't speak for @julian-wolf(fit looks great to me though!), and I'd be very interested to hear his thoughts, but I've also been dissatisfied with corduroy options- for whatever reason I'm just not that into corduroy jeans, but I'm not ready for full tailored trousers in corduroy, either. 122 is directly based on 132, with the same amount of seat shape taken out with a vertical pleat rather than a horizontal/diagonal yoke seam. Sizing is equivalent. I don't know how to quote across threads, but in the Wide Jeans Thread @chicote said "the tender 132 as a wide fit option — again, just my experience wearing a size 2 (roughly 1 inch oversized on me) which I felt like I was swimming in years ago!". Not quite sure if this is what he meant, but his comment reminded me of something that I was told when I worked at Hackett in London 20 years ago (now more fashion/midmarket than it was then, when it was still a pretty legit traditional outfitters, somewhat similar to how Drake's is now). I was told that Hackett neck ties were always 'the right' width, but that that subtly changed every so often, so that within the broader fashion context they didn't look unusually skinny or wide. I can't remember who it was that told me this, but they also said that this was the same with Levi's 501s, which isn't actually a set pattern at all, but changes/d with the times (as we know). Looking at 132s and the 122s which I'm wearing at the moment, they were originally intended as a wide fit, and the pattern has never changed at all, but over the last 13 years they now feel more like a regular fit to me, with 130 seeming quite slim. Granted I may personally be growing into them (ahem), but looking at Julian's 122s I think they just look 'right' rather than notably wide or high-waisted.