-

Posts

2396 -

Joined

-

Last visited

-

Days Won

53

Content Type

Profiles

Forums

Events

Gallery

Store

supertorial

Classifieds

Posts posted by Foxy2

-

-

0736style are great guys - visited their "shop" about 2 1/2 years ago - not very versed in the English language, though...

0 -

I'm generally a W32 in most Japanese brands - and a W31 in RJB and Fullcount (for their more relaxed cuts).

In SDA I'm more of a W33, especially for cuts like SD-103.

I recently got the SD-515 (which is a SD-103 cut) in W32 and their are uncomfortly tight at the moment. I think/hope I can stretch and wear them enough to make it work, but I should have gotten them in W33...

0 -

I'm convinced one will not be able to just see the difference.

It is more likely a combination of things:

- the yarns used (modern machines run at higher speed with considerably higher friction/tension on the yarns - certain yarns that can be used for loop wheel machines can not be used on modern machines, notice the lint in videos...)

- the hand/hand feel

- the loop formation process and result

- differentiating between loop wheel and sinker wheel knits may be even harder

- certain effects and loop types are not possible on machines with fixed needle bars

Similar to the horse hide - steer hide issue a while ago looking at the whole hide is the only way to be certain (genetic test is not an option for loopwheeled tees...)- in regards to loop wheel/sinker wheel:

- know the brand...

- know the agent or factory they work with and produce at...

- know the machine brand/type used...

4 -

Nice outfit!

1 -

Nice one Foxy.

Sorry for the dry & academic detour - let me know if you need exact citations...

1 -

David J. Spencer makes a few specific comments throughout his book (Knitting Technology) in regards to sinker wheel and loop wheel frames:

- particularly suitable for plush and inlay fabrics and loop transfer

- accurate control of the loops possible

- more gentle & careful loop formation

- not able to move single needles

- only single needle beds

- low productivity

... became pretty much obsolete as soon as the first technically and commercially viable latch needle machines showed up in the market.

1 -

Some contemporary comments copied from encyclopedia Britannica, 11th Ed. under the term - Hoisery:

....

Circular Frames.

The English loop-wheel circular frame is constructed with spring needles arranged with the springs facing outwards round the circumference, and the fabric proceeds up wards to be coiled round winding-up rollers. This machine is specially adapted for making what is known as fleece-lined fabrics, as it has facilities for making fabrics where a thick thread floats on the back and is afterwards brushed and rendered fleecy. The machine can also be adapted for working imitation astrachan and fur-like fabrics, and it is also used for the thicker and denser textures suitable for suitings and overcoatings, the fabric having the knitted origin obscured by the brushing operation.

The French or German circular frame is another type of spring needle circular, where the needles radiate from a centre and are set in a circle with the fabric proceeding downwards. This ma chine has been adapted for the production of plush and velvet fabrics, mostly in artificial silk, where the lustrous yarn is brought to the surface with a longer length of loop which forms itself into a pile which can be cut or left uncut as desired. American machine builders have worked steadily forward production of both spring and latch needle machines of finer gauge or cut. The results are borne out by the 30, 34 and even 4o cut machines in use—the latter having 4o needles to the inch. Due to the wide-spread use of rayon, or artificial silk, and the resultant tendency toward finer fabrics, machines, such as 32 and 36 gauge are considered obsolete while the 42 gauge (28 cut) machine ranks supreme for under wear fabrics of quality. These fabrics have a wide popularity for dress goods, and they afford one more instance of the way in which the knitted fabric is invading the realm of the older woven tex ture. The finer denier of artificial silk combined with the deli cately set mesh of the fine-gauge knitting machine make it possi ble to produce fabrics of gossamer-like consistency for every tex tile use. In the newer adaptations of the Jacquard principle to the circular machines all limits to the scope of knitted design have been broken down, and it is now possible to produce fabrics with a repeat extending the full width of the fabric.

Development of hosiery machinery in America was principally along the lines of circular machines of the automatic type. An example of such machines is found in one type which starts knit ting, and after finishing the garter welt, turns, knits it into the body of the stocking, knits in an imitation seam at the back (in simulation of full-fashioned goods), enters the splicing yarns in heel, sole and foot, and automatically knits in gores in the heel and toe sections. The stocking leaves such a machine fully completed except the toe join or seam and dyeing and boarding. Fully auto matic hosiery machines, although imported in large numbers, are manufactured in America in two plants, one of them being the largest manufacturers of this type of machines in the world.

....

1 -

Some textbook action:

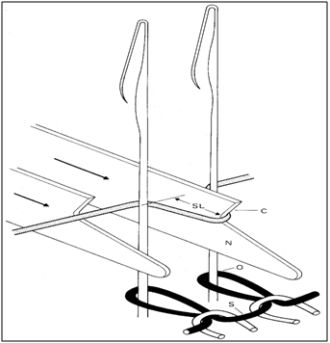

On bearded needle weft knitting machines of the straight bar frame and sinkerwheel type (as on Lee’s hand frame), the main purpose of a sinker is to sink or kink the newly laid yarn into a loop (Fig. 1) as its forward edge or catch © advances between the two adjacent needles. On the bearded needle loopwheel frame, the blades of burr wheels perform this function, whereas on latch needle weft knitting machines (Fig. 2) and warp knitting machines (Fig. 3), loop formation is not a function of the sinkers.

The second and more common function of sinkers on modern machines is to hold down the old loops at a lower level on the needle stems than the new loops that are being formed, and to prevent the old loops from being lifted as the needles rise to clear them from their hooks.

Source: knitting technology (one of my old textbooks way back in the day in MMU, Manchester)

It gives you a basic idea about the principle and some of the differences to modern circular knitting machines.

5 -

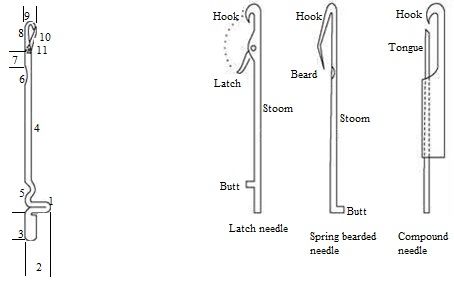

The significant features are:

- bearded/spring needle

- fixed bar, single needle bed

The different needle types in overview:

8

8 -

Somewhere in the midst of this debate, has anyone explained the difference between a loopwheel machine and a standard tubular knit machine (if there is such a thing)?

...

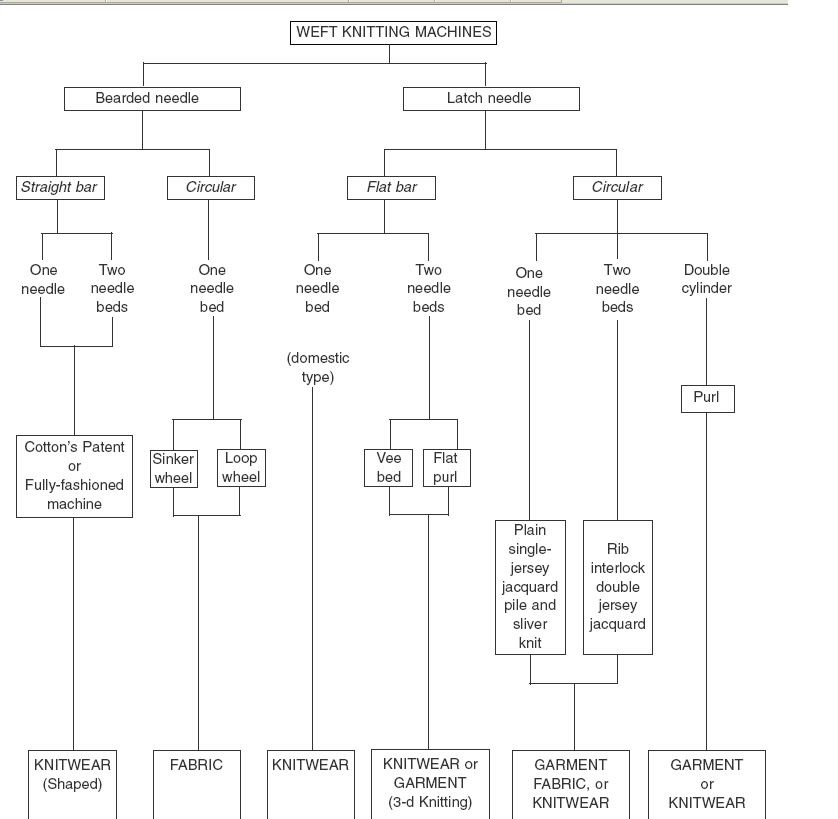

Here is an overview that gives you an idea where Loop wheel and sinker wheel machines fit in:

Source: handbook of technical textiles

8 -

the excess tension cited might be in comparison to the 'newer' circular-knitting machines.

here's one example of a 1950's circular-knitting machine at work, from Lee Kung Man

the raglan is made of Swiss cotton, not made in Switzerland.

well i may be wrong on both counts, do feel free to correct me

Lee Kung Man - is on my list, need to pick up something next time I'm in HK.

The LW Swiss Tee is indeed Swiss cotton, not Swiss made. Very nice, heavy tee - just wore mine the other day.

0 -

...

when some says "most machines are made in japan ... then they say, oh wait, "most are from euro," you dont need to be a lawyer to say ... um, wtf?

...

I said that I believe that the majority of the still existing/operational loopwheel machines in Japan are most likely of Japanese origin.

For various reason, I tried to explain a few...

Same as most of the European loopwheel machines are of European origin (or have been, whatever is left of them outside of museums).

I don't recall comparing the size of the Japanese industry to the European.

0 -

yes, thank you captain obvious.

i was interested in why you came in the thread and proclaimed they all the machines were in japan were either, japanese made, or were copied. these are your words. then, in no more then three posts later you say they are from euro? what the fuck?

now, i see you copy and pasted an lw interview. okay, but what do you know of lw? i thought you had some prior knowledge of the machines. now, i think you are full of shit.

...

That's what my dad says...

On another note:

Not so sure what you were expecting?

No, I don't have a loopwheel machine at home.

No, I don't run a factory using loopwheel machines.

I am industrial tailor, pattern maker and have a engineering degree in garment engineering.

I spend the last 30 years working in the garment industry, but I'm not a loopwheel or knitting specialist.

I have been interested in loopwheel fabrics and other fabrics and machines from the area for a number of years.

The brief history of circular knitting can be easily googled by everybody - the early concept of the loopwheel machine goes back to England or France (Marc Isambard Brunel, French born, English engineer patented a circular loop wheel knitting machine).

Industrial loopwheel machines have been produced since the early 1900's.

I was sceptical about the statement that the machines currently used in Japan (according to LoopWheeler they are from the 1920's) are actually American or European machines.

As of now we have to take LoopWheelers word that the machines of the 2 remaining Japanese factories are build in Japan.

2 -

I just googled both German manufacturers you named and it's interesting that they both come from the same German city (Albstadt). And it's also the home town of Merz b. Schwanen.

So you can say Albstadt (near Stuttgart) is kinda the German counterpart to Okayama

edit: you beat me to it

Merz (not Merz b. Schwanen) is another early Loopwheel machine manufacturer from Germany.

Don't forget Saxony (Plauen and region) as the other, older center of German knitting history...

1 -

^^ That's what they told me 3 years ago when I was visiting their shop in Tokyo - didn't ask them for a ratio and I haven't checked if it has changed lately.

I am following them on their blog for a number of years and own a few of their pieces over the years.

2 -

Double post

0 -

and from Germany itself: http://www.merz-schwanen.com/en/manufacturing/

http://www.merz-schwanen.com/en/gallery/

perhaps i may be sadly mistaken but those are loopwheel machines, no?

Merz b. Schwanen is clearly labelling them as Rundstrickmaschienen from the late 1920s as well as 1950's - I am sure Peter has done his homework in order to not mislabel them Loopwheel if he knows better.

1 -

Some more background info:

According to LoopWheeler there are still 2 factories left in Wakayama using LW machines. Any other japanese manufacturer is supposedly not using "LW" machines. The one factory that LoopWheeler collaborates with has about 100 operational machines and about another 100 in stock for spare parts.

In the above mentioned interview they mention the German origin of the Loopwheel machine itself -my guess is that they refer to Mayer & Cie. as the German manufacturer of the first "modern" industrial loopwheel machine in 1906. Mayer continued producing these machines at least until 1939.

1 -

Most of what they do is collaborations and therefore not available on their own website/web store.

If you check out their regular website you get to see most of the projects they are working on and sometimes they give you am idea about the prices.

I just placed my first order with their new international web store - did use proxy in the past or showed up in the store in Tokyo...

1 -

Here you go...

The 1920's looms LOOPWHEELER is using, are a very long way from home, Germany, to be exact. Do you have any idea how these found their way all the way to Japan?

According to a specialized textbook from Wakayama, the loopwheel was first brought to Japan around 1890 during the middle of the Meiji era. At the time it was called a Switzer, with most being made in Switzerland or Germany. In the Taisho and Showa era, these machines were slowly replaced with Japanese-made counterparts. Today, only the Japanese machines remain in existence. However, another theory asserts that the machines came to Japan aboard ships from Holland in the last years of the Edo period. So, the historical account remains divided. If a machine breaks, usually a craftsman will repair and adjust it. The sewing needles in the machines are exclusively from the German company Groz-Beckert. In addition, we carefully keep additional non-functioning loopwheel machines on hand to use for replacement parts.

Source:

http://thesavile.com/JANUARY-2011/11/keeping-pace

Still no name of the Japanese machine manufacturers!

3 -

We are talking about identifying the machines, at least I was...

Gimme a machine manufacturer name, a model number or a year and we can try to do some research.

Without facts it's just another myth like "Cone Looms" in Japan (looms used previously by Cone, bought and imported to Japan) or lost in translation...

4 -

Warehouse online shop sells overseas

(at least that's what they told me 2 years ago)

Yes, they do - get ready to pay customs and taxes, though.

0 -

...

i know there is a huge issue of copies and what not in clothing manufacturing (in all parts of the world, including japan), but i always thought the lw machine in the lw factory are not of japanese-origin. are you saying this is not correct, at least as far as the lw factory is concerned. i could care less about stike gold, etc as they just buy what is put in front of them and do not manufacture the fabric.

If you are referring to the loopwheel on display in the front window of the LoopWheeler shop in Japan I have to say that I didn't bother asking them - it is a museum piece, that's the reason it's on display and not in the factory.

Loopwheel machines have their origin in Europe from where the machines, the technology and the patents spread out into the world. Different countries and companies enhanced the machines and technology, eventually licensing the technology and/or registering their own patents.

So far I have not been able to identify any European or American machine manufacturer in any of the photographs form Japan, none of the interviews or reports I have seen mentions European or American machine suppliers.

I am sure that there is the odd machine from Europe still left in some Japanese museum, similar to the initial power looms that Toyoda bought and imported to Japan before they began licensing the technology and developing their on own power looms.

What sets Japan apart from the rest of the world is that somehow some loopwheel machines survived while for the majority of the world these machines got replaced through more "advanced" & "efficient" machinery.

3 -

They could leave it loomstate. Why bother sanforizing.

...

My point is that the whole construction does have to produce a stable, washable fabric (with or without further treatment) - just leaving the fabric loom state is not feasible option if the washed fabric falls apart.

(Unless somebody gives a shit about their customers - selling jeans that can not be washed...)

0

Loopwheeled/Vintage T-Shirts

in superdenim

Posted · Edited by Foxy2

So, I did send a question about the name of the machine manufacturer to LoopWheeler's customer service - no big expectations, but let's see if we get a reply...

Here is a picture I borrowed from Merz bei Schwanen and their website:

(Again, please take note that Merz b. Schwanen does not make any statement on their website about their machines being loop wheel machines!)

It probably shows the transmission head/center pole that drives the cylinder/needle bar - it is a Alber & Bitzer from 1940. Apparently, the company still exists under the name AlBi Alber & Bitzer Maschienenfabrik in Albstadt, Germany.

Due to the machine type and build (no engine block - only transmission) of old style loop and sinker wheel machines I would guess that finding these machines supplier & serial number plates will be difficult, especially in photographs. Most of the machines are arranged in customized settings and probably reconfiguration multiple times over the years. If the plates have manged to stay on certain machine parts, these spots will most likely not in direct view...

I have even going through some of my old magazines - randomly - and found some more pictures in the Dayton Bros Samurai book from 2011 and maybe some more in the Lightning Tee book. I will try to take some pictures and post the soon - maybe we can get somebody to translate the page scans at one point...)