-

Posts

301 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

supertorial

Classifieds

Posts posted by ItsJustNC

-

-

Prototype 2 slot card case. Was wondering if there is a market for it. Would appreciate some suggestions..! Thanks in advance.!

0 -

Ah... Looks nice and even.! Haven't tried my hands on water based dyes though. I've read that its not as penetrative as the alcohol based ones.

What do you think about it.? Because i've read more nasty reviews than good ones about it...

0 -

-

I have around 15 belts that fit in with the hobby...also have a bunch of dressy belts but I never wear them any more.

How the hell do you keep your gears without getting them moldy dude.? Made yourself a dry box or something.?

0 -

Royal Meadow is great stuff, best moisture content of any veg tan I've gotten my hands on. I just wish it was available in 2-3oz.

I know what you mean man. I've been trying to find a better one than craftoak. And im avoiding the petite goat hide purely because i have this ocd thing where i want the guts to be bovine too.

0 -

^^^ Yea man, im using royal meadow too.! Its pretty good and blemish free. People give them too little credit...

0 -

^^^ Just a cheap ass cutting mat.

0 -

what dyes did you use for that? it looks amazing

Thanks dude.! It just Fiebing's spirit based dye. Tan.

0 -

Ah, thanks for your advice, NC! I imagine that it's much easier to cut shapes like that with a laser, but you've confirmed my suspicions about the edges. I am guessing that it might not matter much if the pieces were going to be dyed and have the edges burnished, but half the stuff I make is natural. I'll go back to planning on ordering dyes... I've heard it's fairly easy to make a press with a car jack? I see a 6-ton shop press on Harbor freight for $65

No problem dude.! Laser cutting is accurate and versatile but cost effectiveness wise, you'd be better of with a die cutter. Cause laser cut machines are just high maintenance. Not to mention, the fact that you're gonna do high volume cutting, the mirror inside might overheat and crack. Replacing it will be a bitch.

And i guess, thats why boots making companies like redwings still stick to using clicker press and die cutters.

Yea, I've heard people using shop presses and arbor presses to die cut. But i would believe that the safest bet would be a decent clicker press.

0 -

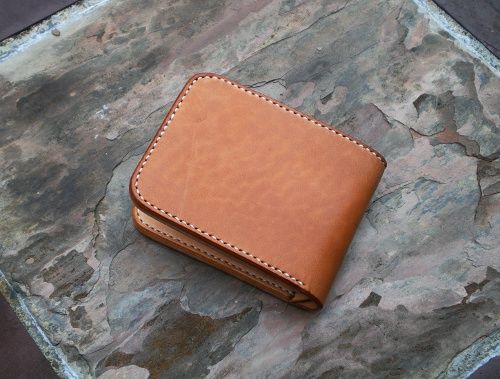

Anyways... Something i just made earlier on.

Hand dyed. Burnished. 6 card slots. Card case wallet.

3 -

In other news, I am seriously considering switching to laser cutting for key chains and card cases. I simply can't keep up with demand, and it would allow me to cut and dye large numbers at a time. The other option is to have a dye made, but then I need to find a suitable press.

My New Year's resolution is to cut production time, since I'm tired of spending every night individually cutting and dyeing each piece. I'm also planning to just offer 2 or 3 different buckles so I can cut a lot of belt blanks at once.

This couldn't have come at a more perfect timing. I've just tried out using a laser cutting machine for high scale production. Dude, you'd be better off with an arbor press and die cutters.

I've been making leather key chains for a school fund raising, and I have access to a laser cut machine. So i'd thought i'd try it out, and well.... The results aren't as desirable as expected.?

You tend to get singed surfaces from the lasers (I've actually tried calibrating the power and speed many times and the end result is still the same.)

It's really annoying trying to get the leather to lay perfectly flat, because the laser cutting machine needs a flat surface for consistant results. (You can try sticking it on a piece of acrylic but its just plain troublesome.)

Though the edges looks nice and black (Kinda resembles dyed edges) It is actually covered in soot that will rub off and stain, especially for natural veg tans.

The result is inconsistent, so you can have one perfect batch with minimal burn marks, but another batch covered in burn marks. Curiously enough, its the same leather from the same cow with the same EPS file with the same exact settings. But i guess that's just the way it is.

You would get more cleaner and consistent pieces with a die cutter. And if i'm not mistaken, at a fraction of the price too. It may be troublesome making a new die for every new design, but i would think that its more worth the money spent. The only cool benefit fo a laser cut machine would be the engraving you could do.

2 -

Zissou. This color is so sick! I have limited experience playing with dye. What do you guys use to seal the leather so it doesn't bleed? Not a fan of the shiny plastic look of some sealers.

Firstly, use spirit base dyes.! Those stuff doesn't rub off as easily. Secondly, try making a leather balm out of beewaxs and neatsfoot oil, it isn't that tough and it works really well.! You get a nice natural matt finish that can be buffed to a satin shine.

Just a simple 1 : 1 Ratio could do the trick.!

0 -

SICK... Now i really wanna try some croc skin...

0 -

The buckle looks fucking great.!

0 -

Manually with water and a wooden slicker.

0 -

Ah... I think i might have been a wee bit rough, thats why some of the burnishes on the card slots are thicker for that piece. I did use a rag and gum trag too, but it keeps slipping... After this piece, i haven't been burnish card slots. After seeing yours, i think i might wanna try one again.! I think this time round I'm not gonna bevel it.

Oh no dude, that is a wallet.! Haha.! A bifold i made in May last year.

Oh yea, hows gum trag suiting you.? I stopped using the stuff and switched to good ol' water. Its a bit to slimy for my liking. And the fact that i'd have to buy and ship it is a pain. I get better results with water anyways.!

0 -

Ahh.... I see... I guess it must have been a trick of light or the angle. It just looks really thick in the image.! Haha.!

But damn... I can't seem to get over how even the burnish is on the card slots.! I hate doing it cause 2-3oz tends to crumple and it gets a lil uneven at some parts of the burnish.

0 -

Some Horween veg tanned horse butt

Great burnish as usual dude, Liked how you actually creased and burnish the edge of the card slots so nicely. But it looks like a monster to carry.! What oz did u used for the guts and shell.?

1 -

I know you guys always go around telling to check out the 'local leather crafting store'-so to speak- but as far as i know there are barely any of those here..

And i have no experience with buying things online.. maybe this will be a start..

Thanks for the replies anyways good sirs!

There ya go. Looks promising. Just a quick google search and this is what i got. Its in Bandung.

0 -

I want to start but I live in Jakarta and i have no idea where to get tools and leather..

I do occasional trips to Singapore and was hoping someone from OGL, itsjustNC, or lazybum to give me info on where to get such stuff there.. Please, good sirs? *puppy eyes*

Haha, i don't know about the rest but personally, i find that theres almost no leather supplies for tools in Singapore. I think you're better off sourcing around Jakarta. Worst case scenario, Theres always the option to order online. Tandy leather recently opened a branch in Australia. New South Wales. Minto, So the shipping shouldn't be so taxing on you.

0 -

On top of what mike said, i'd like to add another point. I feel that when it comes to raw leathers like veg tanned leathers, moisture plays an extremely big role.

This is a case i made for a friend. It was wet-molded. And my friend put it inside his pocket before it was completely dry, and the slightly damp leather actually managed to capture the twill of the denim in an indigo print stain. It was only in his pocket for half an hour or so.

This here is a card case i made for my girl, she had this card case in her back pocket of her denim and she sat on a wet bench. The water from the bench seeped in her denim and bled on the leather, creating this bruise-like stain on the top left. You can actually see the contrast in darkness of the pores. Apparently, they absorb more indigo.!

And lastly, this here is my satchel, this was how it looked like after a month of use. It was never exposed to water since i made it and used it during the whole first month and this is how the indigo stained it. A very gradient stain.

So main point, quality of leather doesn't affect staining.

1 -

^True that. They should let patients burnish to diagnose their mental condition.

Mirror-like = OCD

Some parts mirror-like some parts fuzzy = Schizophrenic

Fuzzy = ADHD

1 -

Something a little different, Clayton bridle leather made into a belt loop holder by Scott Willis:

Very cool Damascus button:

Its like something that came out of a fantasy world that has metal alloy trees... Then someone grabbed a branch and lathe this Sam Browne Stud out...

Video Santalum - The making of handmade Goodyear Welted Construction

Please don't hesitate to give us critics & comments

The part where he grooves with just a knife is freaking mesmerizing.! *Grabs knife and scraps.!*

0 -

Gonna try my hands on some metal working.!

0

Leathercrafting Creations: PYC

in supershopper

Posted

Yea, I was thinking of a big slot at the back... And i only know one person who packs this light. So i was wondering if i was ignorant or i have weird people around me