GriffingAve

-

Posts

50 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

supertorial

Classifieds

Posts posted by GriffingAve

-

-

Just trying to get my head around this! So what would the difference be in attaching this http://www.ebay.co.uk/itm/Singer-Walking-Even-Feed-Foot-/160761974290?pt=UK_Crafts_Sewing_Supplies_MJ&hash=item256e290e12#ht_500wt_1202 to a machine (that previously didn't have a walking foot) and using a machine that already had a walking foot?

By the way, I think I'm gonna try my luck with a Singer 201K as they seem to be the most readily available in the UK.

Thanks

Have you seen this thread? It will give you all the answers you need and more.

0 -

Another quick question. How's the water repellency after your hot stuffing treatment?

Andrew

0 -

Very interesting. Definitely need to experiment more. I make my own dressing based loosely on the British museum leather dressing recipe but I use a solvent so I can apply the stuff cold. I'm gonna try different ways to work it so maybe I can do without solvents. I guess more experimentation is in order.

Andrew

0 -

Is this hot stuffing formula a proprietary secret? Is it possible to describe it in general ways?

Andrew

0 -

Very nice. Very clean. Did you hand sew or machine sew this one?

Andrew

0 -

After looking at the sewing machine talks, i decided to look around my area for one. I am sewing some wallets and other kind of accessories mostly 2-4 oz i guess. So i was wondering if something Juki Sewing Machine DDL-8300N would be something i could use. Maybe adding a walking foot to it? Totally new at this sewing machine thing so any tips would be greatly appreciated. Thanks in advance!

A Juki 8300 is an industrial sewing machine with a regular presser foot (not a walking foot). Although some folks sell a "Walking Foot" attachment for home machines (not sure if such an attachment is available for this machine), those aren't really walking feet. What you'll notice if you use a machine like this is that the leather will tend to slip, especially going over seams and bumps and you'll get uneven stitch lengths if it feeds at all. Also, in order for these machines to feed, they use the feed dogs on the bottom to grab the material and that can mark up the bottom side of your leather. Not sure how important this is but something to keep in mind.

Andrew

0 -

Thanks for the quick replies guys! Honestly I just don't want to spend a lot on a sewing machine as I am just beginning this, like for whatever reason if it doesn't work out I will have wasted a lot of money, though I guess I can sell it again....I think i'm gonna look for the ones you recommended superjunkie and then if I really like what I'm doing I won't mind investing a lot more into it. Now ima play the waiting game till I find something for a good deal.

Buying your first sewing machine for leather is a scary proposition cause you really have no idea what you need and what different machines will do for you. Craigslist is definitely a good resource. Generally look for machines that say "industrial walking foot sewing machine". What area do you live in? I live in the SF Bay Area and there's a few on Craigslist that's listed in the $650 range. Might be closer to your budget (I saw a really nice machine a while back for like $450 so deals are out there).

Bear in mind though that whatever machine you get on Craigslist will probably be geared towards upholstery sewing which means that it probably has a very fast clutch motor. You might want to budget in some extra money to replace that will something called a gear reduction servo motor ($150-200). It'll help you control your stitches much easier and sew a lot slower.

BTW, you might also want to look into something called the Sailrite LS-1. Folks on Leatherworker don't like them but since you're not working on super thick stuff, it might work just fine for you. It's a portable walking foot sewing machine mainly designed for sewing sails and canvas and stuff but should be able to handle thinner leathers. They can be found pretty cheap used ($300 range?).

Anyways, good luck.

Andrew

0 -

Here's a wallet leash I just finished. Made the belt hook myself.

5

5 -

He's using some sort of PVA (PolyVinylAcetate) cement. Tandy sells something like that called Tanners Bond Leathercraft Cement. The reason I say it's PVA cement is because of that plastic glue tub he's using. The other general type of cement is contact cement (sold either as Tandy Tanners Bond Contact Cement or Barge Cement). For contact cement you have to use a teflon glue pot or else it'll stick the lid completely shut.

I use both of these glues. Contact cement is a much stronger bond than PVA cement. You basically put the glue on each of the two contacting sides to be glued together, wait for it to dry until the glue is tacky, and then stick the pieces together. You have to be careful cause they basically bond right away so you have to make sure you position the pieces carefully cause you really can't reposition them.

With PVA glue, you put the glue on one of the two sides to be glued together and push the pieces together wet. This gives you some time to reposition the pieces as the bond will take a bit to set in.

There is a third basic type of glue which is rubber cement. Works kinda like contact cement but the bond is not as strong as either. You can peel the two pieces together even when the glue is dry.

I basically use PVA if I just need to tack something together for sewing and I use contact cement if I need a permanent bond that needs some strength to it. Hope this helps.

Andrew

2 -

Looks good! Coincidentally I just finished my own take of the postal bag too as an experimental foray into the world of full sized bags.

Got any pics?

Andrew

0 -

Alright thanks for the quick reply! Now to look into getting a sewing machine.... Can anyone recommend a good cheap one I can begin with that can handle around 1mm thick leather. From what you're saying I gather that I don't need a stitching awl, etc either? All i need is a sewing machine, needles, sewing thread, leather and patterns, and zips if needed I guess? Also, sorry to be asking so much, but anyone have any websites that'll help me get started with patterns and type of stitching needed in different situations? Really appreciate the help!

Thanks

Go to leatherworker.net and look in the sewing machine sub forum. There's a pinned thread at the top on choosing a sewing machine. You will get more information then you'll ever need on the subject. Keep in mind though that that forum is geared much more to folks that sew holsters and saddles so they will always recommend a heavyweight machine. With that said, a home sewing machine will have a hard time even with 1mm leather (considering that most sewing will be two layers a least and some seam areas may go up to three or four. You're talking about more thickness than those machines can handle). Ideally a compound feed walking foot machine is better but of course they are very expensive but if you know what you're looking for, good deals can be found on Craigslist. Also, if you're gonna get an industrial type machine, get one with a servo motor, especially of you're new to sewing leather. You have much much better control than a clutch motor.

Andrew

0 -

You can hand stitch a wallet but in general, the aesthetic of the stuff in your link would be better done by machine. The reason is that hand sewing generally uses a thicker thread so it has a chunkier (not In a bad way) look. Also, a lot of these fashion wallets use very thin and soft chrome tan leathers (under 1mm) and it's very hard to hand stitch them well because the stitches tend to bunch if you're not careful about how much tension you apply (this is less of an issue with thicker, harder veg tan leathers because the leather itself offers more resistance). also,mkeep inmind that if you want to hand sew that bag in the second link, it'll take you like 40 hours because of the number of stitches required. I know my first bag did...

Andrew

0 -

Here's a bag I just finished tonight. It's the first bag I've done on my sewing machine. I have an old J Peterman replica US post bag which I used as the basis for this project. This bag is a copy of the J Peterman with a few small changes to suit my tastes. I guess I did this bag as a study in design and construction.

Andrew

3 -

I design my patterns in Google sketchup. Very easy to use. I then export them to a .svg file and import them to my wife's automatic paper cutter. I use some heavy card stock (140lb. watercolor pads) and cut them out in the paper cutter. They make great patterns. Sketchup is great cause you can make sure all the dimensions of all the pieces fit which is harder to do when you draw by hand.

0 -

Ok, so here's what I've been working on. I don't think that solid copper sam brown studs would be an affordable option, at least not that I can find. And with copper being so soft and pliable, I don't think they'd work very well anyways. But I have gotten in touch with a guy who does copper plating, and it sounds like something that would be actually pretty affordable to copper plate a bunch of brass sam browns. His minimum order was only 300, and I think they would come out to around $1.50 to $2.00 a piece. That price would include the cost of the brass hardware and the copper plating. The plating can be applied at any thickness from .00005" to .0035" (pop cans are .003" thick). I was thinking somewhere around .002". How many people would be interested? I'll probably do an order of 300 myself at some point, but let me know if we want to do this sooner. I'm not in any rush.

I'm interested too. Just make sure the screws still fit when the plating is done. Changing the tolerances by .002" could possibly be enough to make the screws no longer fit.

Andrew

0 -

Here's a couple of pieces I had to make for my school portfolio:

Big bag

Bike wine carry

Essentially the big bag can be worn as a backpack, as a messenger bag, or with no straps. I have a blanket roll that I can fit inbetween the big bag and the small bag for some urban sherpa park life.

Nice bag. Do you have some shots of the interior?

Andrew

0 -

i'm actually making a little bit of headway on this idea - i'll keep you guys posted. i think a giant superfuture collective order may be in the near future. would people be interested if the price was right (looks like it would be)?

Definitely yes. Would you be able to get different sizes?

Andrew

0 -

hey guys, another hardware question...

i'm looking for some copper sam brown buttons. i need to put one right next to a copper rivet on a design i'm working on, and i hate the look of copper and brass/silver together. anyone have any good ideas or good sources? i've been looking online for about an hour. i could replace the rivet with some stitching or something, but i love using the rivets in a functional role whenever possible and stitching just wouldn't be the same...

i know copper isn't very strong, but i think it would be ok in this design.

I've looked for days for Sam Browne buttons (I was looking for small ones) and I have never come across a copper one. Might be better off thinking about a different alternative. Of course I could be wrong. And if I am, please let me know cause they would be nice.

Andrew

0 -

Great looking wallets! Though looks like the card pockets in the dark brown chromexcel are leaving an impression on the other side?

No. I used that wallet for a day or so and the credit cards left an impression. Some leathers definitely mark more than others.

Andrew

0 -

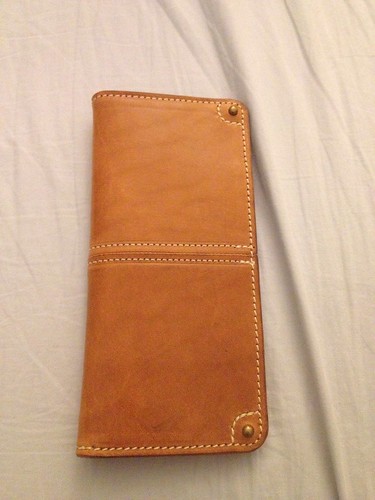

A few wallets I just finished:

Clockwise from top left.

1. Cognac Shell Cordovan

2. Natural Shell Cordovan

3. Chromexcel horsebutt in some dark brown color

4. Tan dyed veg tan horse butt outside with natural veg tan goat inside and red dupioni silk lining.

Any comments appreciated.

Andrew

3 -

Something wrong with your shell?

I just finish it with a damp cloth polish.

If its a little scratched, you can always do a very very very very ......very light coat of shoe polish wax.

Don't use shoe cream unless you want to spend a hour repolishing the whole piece......

Most of the time a damp cloth will do wonders on shell cordovan.

Thanks for the info. The shell looks fine. There's one or two light scratches on it but nothing major. I was just wondering if it is necessary/beneficial to apply any type of finish. Maybe to get a bit more of a shine to it. I have a dressing that I make that I put on regular veg tan stuff but Shell Cordovan's another type of beast and I don't want to go around messing it up (since it's so crazy expensive). Thanks for the damp cloth suggestion. I'll try it out.

Andrew

0 -

I have a question for all the folks here that use Shell Cordovan for your work. Do you guys put any type of finish on the leather after making the piece or do you leave it as is? Looking for some ideas here. Thanks.

Andrew

0 -

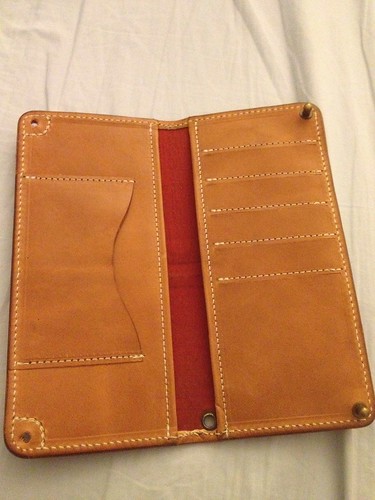

Hello all. I randomly came across this thread and I must say that I am very impressed with all the work that I see here. I want to introduce myself to this thread and show so of the things that I have made in the last few months.

I've been doing leather crafts for about a year now. I mostly go on the Leatherworker.net forum for help and information but I find the aesthetic of this thread much more suited to my tastes than Leatherworker. I live in the SF Bay area (Alameda) and have started selling a few of the things I make at a local store. This is a hobby for me really but hopefully a few sales will help pay for more toys!

I've pretty much skimmed this thread from the beginning and it's heartening to see how people's work have improved in quality over the years. I haven't been doing this for very long so hopefully my work will improve as well.

These first two is my latest wallet. It's made with a W&C Russett harness leather. The shell is about 4 1/2 ozs and the inner flaps are about 3 oz. I lined this one with red dupioni silk. This design was started as a suggestion from my brother who wanted a slim wallet. I made it basically just big enough to slip in bills and some credit cards. He wants his in Shell Cordovan.

This is one of several bracelets that I make and sell at a local store. The leather is a drum dyed horse butt and the buckle is a solid brass buckle that I tumble and hammer to get that look.

These are some custom sandals that I made for myself and my friend. These are really fun to make I have to say.

I have a few more things that I've made. I'm hoping to make some really nice bags one day but I guess I'm working up to that. Anyways, any comments welcomed.

Andrew

3

Leathercrafting Creations: PYC

in supershopper

Posted

You can try this out for burnishing edges. I use them and find them pretty nice.

http://www.feltbobs.com/catalog/index.php/

They are felt bobs. The felt is very hard and will provide a good amount of friction for the burnishing process. You can use a file to file in a groove of the desired size so you can have exactly the size you want.

I believe dremels can accomodate a 1/8" shank (please correct me if I'm wrong) so you can use some of the smaller ones on a dremel. As for which dremel to choose, that doesn't really matter. As long as it spins, it'll work.

Andrew