GriffingAve

-

Posts

50 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

supertorial

Classifieds

Posts posted by GriffingAve

-

-

Can you send some pics and info about this Japanese tannery leather? is it a veg tan leather? Chrome tan? Would be interested in seeing it.

Andrew

0 -

Hi Corter, what did you use to imprint the "Declaration" logo on those pouches?

Andrew

0 -

Hm... I actually like your idea in the second picture there. I might try that out for the next bag. I'll have to see though cause with the handle and the D-Ring doubled up like that might make the connection there look too thick. I'll have to play around and see. Thanks!

Andrew

0 -

Looks nice. What is SB Foot leather? What is the thickness of leather you used for the main panels?

Andrew

0 -

I think having the bag strapless would've been better. If you really wanted a strap attachment, I think you should've put a shorter zipper so that the d-rings would fit at the sides. Nonetheless, it's very impressive craftsmanship and it looks very professional. Good work!

Yeah, I thought a lot about where to put the strap. I knew I wanted a strap cause this was gonna be a laptop bag and I knew I wanted longer zippers. I guess this is the compromise that I had to come up with. In a previous rev I had both D-Rings on the same side of the bag but it made the bag list one way when on my shoulder so this was the best solution I could think of.

Andrew

0 -

What's your edging process for the dog collar? Looks pretty nice.

Andrew

0 -

Hm... what would you suggest for the D-Rings? I wanted to put them at the ends of the bag but I don't think that would've worked because of the zipper. Always looking for suggestions on improvements.

Andrew

0 -

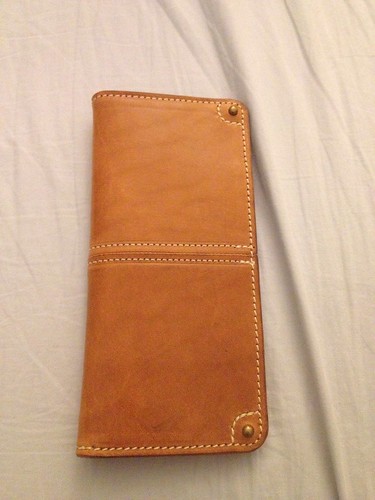

This is the first simple minimal bill-fold I just finished and need some help if any of you have a minute.

1) How do you guys keep the back of your stitches so neat? It seems like even if I manage to get the back looking straight it still looks real choppy and junky (see 2nd picture for reference).

2) In my 3rd picture I have my billfold sitting in my lacing pony. How am I supposed to place the piece into the jaws so I can stitch the sides correctly? As you can see I cant just smash the rest of the bill-fold into that area. Do I just have to buy a real deal stitching pony?

Any other help and pointers would be great. Making things is awesome even if I mess them up all the time!

You're gonna need a longer stitching pony if you want to be able to clamp the whole piece. There are folks that sell better ones or you can buy some wood and make it yourself. It's not too hard to make if you can cut the wood to the correct size and stuff.

Andrew

0 -

Thanks. It's been a real nightmare to make. Who knew sewing piping around tight corners would be so hard?

Andrew

0 -

Here's a bag I just finished. Lots of mistakes but better than the previous few (even worse) bags I made:

9

9 -

Thanks for the info on W&C supplying veg tan to LV. I would've thought they used a French tannery for all of their leather. I do love that patina on their handles!

The guy at W&C told me that LV made some of the stuff here in the US (in California somewhere I think) and for those factories they use leather from W&C. I guess for their European factories they would use european tanneries.

Andrew

0 -

Yep. Thanks!

Man... That's a lot of work. The first two bags I ever made I sewed by hand. I think I got tennis elbow from it (or something like that). I do things by machine now. I think my hands would fall off if I sewed another bag by hand.

Andrew

0 -

To anyone making wallets. Are you splitting your own leather down to 3-4oz or buying it at that size? Almost done a learning batch on some real low grade 2-3oz but I seldomly come across anything high grade in that range.

A manual splitter like a crank splitter can consistantly split your leather down to about 4oz. The problem is that most of them are only 6 inches wide which means you can really realistically expect to put about a 5 inch wide piece through it. That might not be big enough for the main panel of your wallet. I ended up doing something like this for one of my wallets:

Wickett & Craig will split your leather for you if you purchase from them. Their skirting leather (which is basically their straight veg tan stuff but dyed) they will split to whatever thickness you want for no additional charge. If you finish the leather yourself, it can look really nice. Their other leathers can be split as well but they charge you for it.

I ordered some leather from W&C recently. I was talking to the sales guy and told me that they produce leather for Louis Vuitton. It's the leather that LV uses for their trim (handles and such). He said that it's basically straight veg tan except they do a retan on it where they add some other type of tannin that helps the leather age to this golden brown that you see on older LV bags. They only sell the seconds to consumers but you can try that stuff out too. Might be interesting to use.

Andrew

0 -

Nice bag. Was this sewn entirely by hand?

0 -

Just FYI, you can order directly retail from Horween by emailing Eric. Things take a while though since they're a tannery and not a distributor.

Andrew

0 -

Nice bag jaws. Can you show some pics of the inside? Do you line it?

Andrew

0 -

I make a template out of a piece of leather. The template is the same width as the belt. You poke your oblong punch and round punches through it to mark to position. As long as your template is straight, your holes should be as well I would think.

Andrew

0 -

Have you guys tried curved clicker knives? They're pretty good at cutting curves and the blades are very sharp and replaceable.

Andrew

0 -

I bought a six foot long piece of rectangular aluminum rod and anchored the ends at the end of my 5 foot table. The table is covered in cutting board material so I can cut anywhere on the table. I slide the hide (or as much of it as I can get) under the rod and use that as my first cut to square the edge. The I use a strap cutter to cut the straps out.

Andrew

0 -

Black CXL.

been looking into buying a splitter, anyone got one and have recommendations or critiques? Looking as a CS Osbourne one right now.

What kind of a splitter are you looking for? I actually have a Chase Pattern 8" splitter I'm thinking of selling.

here's my experience with splitters. i started out with the tandy high tech splitter. it was ok. they can't go very wide though. also, they can have a tendency to chop your straps because there's nothing above the blade that keeps the leather from flipping up. this tends to happen when you hit a hard spot on the leather.

i then went to an 8" chase pattern pull through. this one has upper and lower rollers so the leather won't chop. they work pretty well. you have to keep the blades very sharp though. the problem is, pull throughs don't work terribly well when you get down to like 3oz thicknesses. the problem is that you're pulling on the leather which, when split down to that thickness, is a lot less strong then it was before and will have much more of a tendency to stretch.

i then went on to a 6" crank splitter. this splitter has upper and lower rollers that are powered by a hand crank that pushes the leather into a blade. the two most common makers is landis and american. this will split the leather down to 3oz thickness. i use this for making wallet interiors. it does not stretch the leather. it actually tends to scrunch up the leather a bit because it's now pushing instead of pulling the leather. when you're using veg tan leather, it's not that big a deal though because the pre-split leather usually is pretty strong. the problem is that 3oz is about as thin as i can go on this machine. although it can go thinner technically, it really doesn't have the precision to split thin stuff well. after all, this thing was made to split shoe soles and not wallet interiors.

of course, the very best thing to use for splitting wallet interiors is a belt knife splitter but those things cost at least $6k used for a decent one. i covet them but cannot afford them.

anyways, good luck with the splitter.

Andrew

1 -

A lot of the first manual's information is very basic, how to make straps and belts mostly. A lot of information on handstitching and general overview info on a lot of tools and different aspects of leatherworking. There is an interesting section on costing your project. I'm actually more interested in the topics of the later manuals (construction techniques for small leather goods and bags) but I'm not sure now if I want to commit to it considering the price.

There's a lot of information but definitely a difficult and dense read.

Andrew

0 -

Is that the manual from the british guy Francis Burdett-Mills? If it is, I have the first manual. Lots of information but a very dense read. I didn't finish reading it though cause the first one has a lot of really rudimentary stuff.

Andrew

0 -

I don't know what your budget is but if you're looking from head knives, there are a few American custom makers that make very good knives. Check out:

http://jcookblades.com/leather.htm

http://www.knipknives.com/leather.php

As for awls, I've used the Seiwa ones from Japan and I like those. They are diamond shaped, come in different sizes, and are fairly short which I look. You can find those from goods japan or eBay. From what I hear, Bob Douglas tools makes the best awls around but I have never personally used them. There's no online catalog but you can find their contact through Sheridan Leather Outfitters (their website seems to no longer be around but if you google them I'm sure you can find them).

Also, if you are looking for edgers, check out http://www.ronstools.com. I have their Montana edgers and they're great for thinner leathers.

Andrew

0 -

Hi Blackgoat. Very nice looking leather. Can you put some pictures of the different variations that you were able to achieve? I'd be interested in seeing it. How does the leather feel? Is it a waxy feel? A greasy feel? Does is soften the horse butt considerable?

Andrew

0

Leathercrafting Creations: PYC

in supershopper

Posted

Very nice tote. The best compliment I can give is that it's very clean and neat.

Andrew