Xin

-

Posts

11 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

supertorial

Classifieds

Posts posted by Xin

-

-

Thanks Falerbrand!

0 -

Nice post raWorkshop!

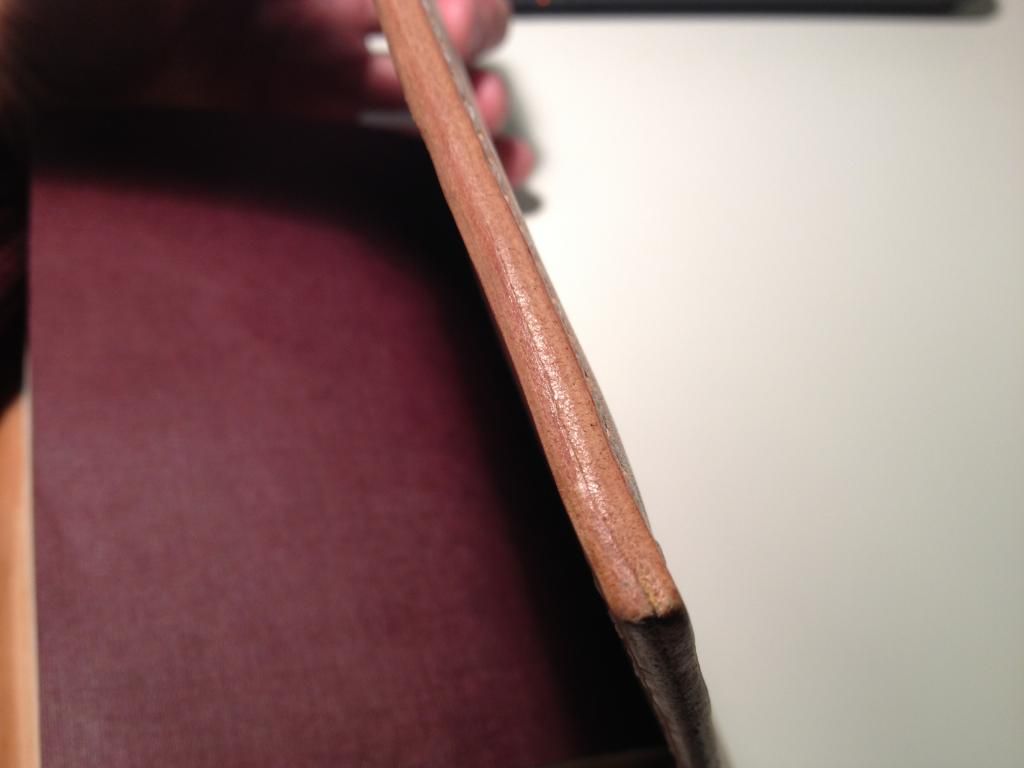

I've been having trouble with cutting for sanding the edge after the sewing was done. I tend to over cut the edge and ruin the whole piece. I found out the some Japanese leather craftsmen use a skiver plane looks like this

but they are too expensive for it's purpose so I did some research and found this:

Not sure if this would work. So if anyone has used something similar I would love to hear your experience with it. I assume the blade is not going to be sharp enough for leather work so I have to resharpen the blade.

0 -

Mark it with an scratch awl (get something with a much finer tip than what Tandy sells). Exacto on the line. Don't cut with your wrist muscles, gently lock your wrist and upperbody and use your lower core and legs to control the motion. Your big muscles will provide the cutting power and your fine motor muscles in your wrists can keep on line much easier.

Karynup - I condition once pieces are cut so they don't pick up hand oils and I don't have to deal with conditioner getting in between my stitches and muddying the whole look.

Thanks! I ordered a round awl from goodsjapan; planning on using it for scratching and poking round holes for corners. I think I'll start conditioning leather after the cut too.

I'm also looking for a replacement for Gum-trag. I know Goodsjapan has "CMC" and some other replacements, but it makes no sense to me to spend twice as much on such replacements. Is there alternate ways to get Gum-trag? Is there powdered Gum-trag on the market? Is there alternatives to Gum-trag?

0 -

How do you guys cut straight line? I used an xacto knife and a metal rule( has a cork side), but the rule always slide down and made my cut went wrong.

0 -

Nice concept!!

I always thought leather has a grading system? Can't remember the exact definitions but you never go bellow medium quality.

Generally if I get a shit bit of leather to experiment with I just have to cut AROUND the really bad bits.

Keep up the good work.

Thanks!

I know that feel. Use it for prototypes, technique proofing (different stitching combination/algorithms) etc. Useful around the workshop stuff like sheaths for sharp or fragile stuff like makers marks.

Great idea! I'm also thinking of using them underneath when I'm using chisels or punches. I can make knife strops with them too.

0 -

This is my new design. I made a mistake by putting it on etsy. I'm glad that nobody bought it. I don't know where you guys got your leather but the side I got was horrible(bug bits, stretch marks).It cost me $120 for 27sf Tandy craftman leather. Recently I found a better supplier which carries Hermann leather. I guess that $120 was a hard lesson for me, so that I won't make the same mistake again. By the way, how do you guys use the cheap, low grade leather?

0 -

Lets talk ergonomics! At the work bench (standing height), I find malleting in a diamond awl leads me to hold and incredible amount of tension between my shoulder blades, same thing with hand burnishing. Has anyone else experienced this? I'm not using a proper leather maul, I use a ~16 oz rubber mallet.

I'd like to stab-n-stitch, awl and needles both in hand but I cant seem to get my awl blades sharp enough to make it work.

Rubber mallets are too soft. I bought a tandy awl blade and then sharpen it with a cheap sharpening stone. It took me about an hour to get the sharpness I want(get through two layers of 4~5oz like butter. Strop your blade also helps(if you have a sharp awl). I also use bee wax to lubricate.

0 -

-

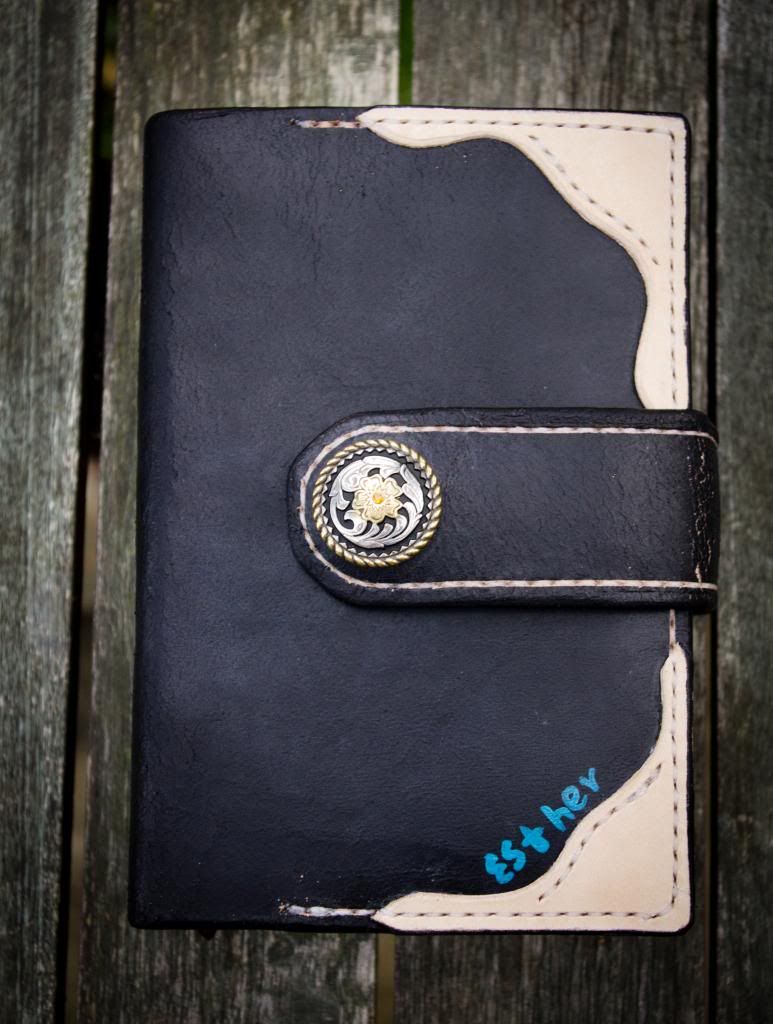

sorry the color suppose to be turquoise, my laptop screen is off.

3 -

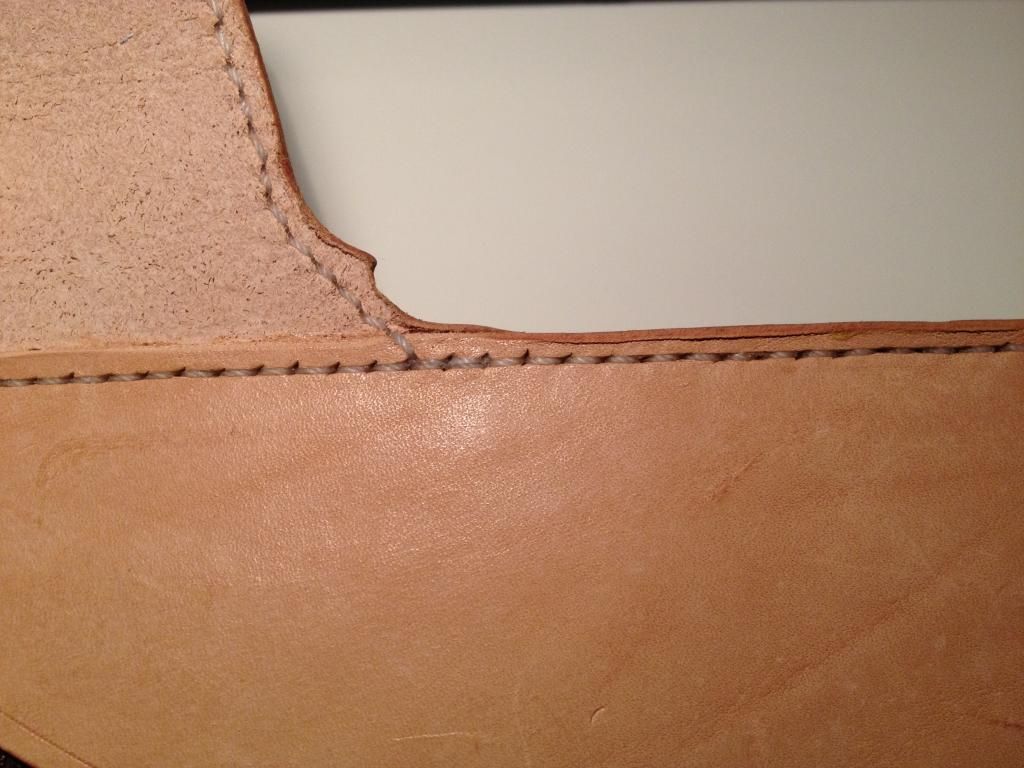

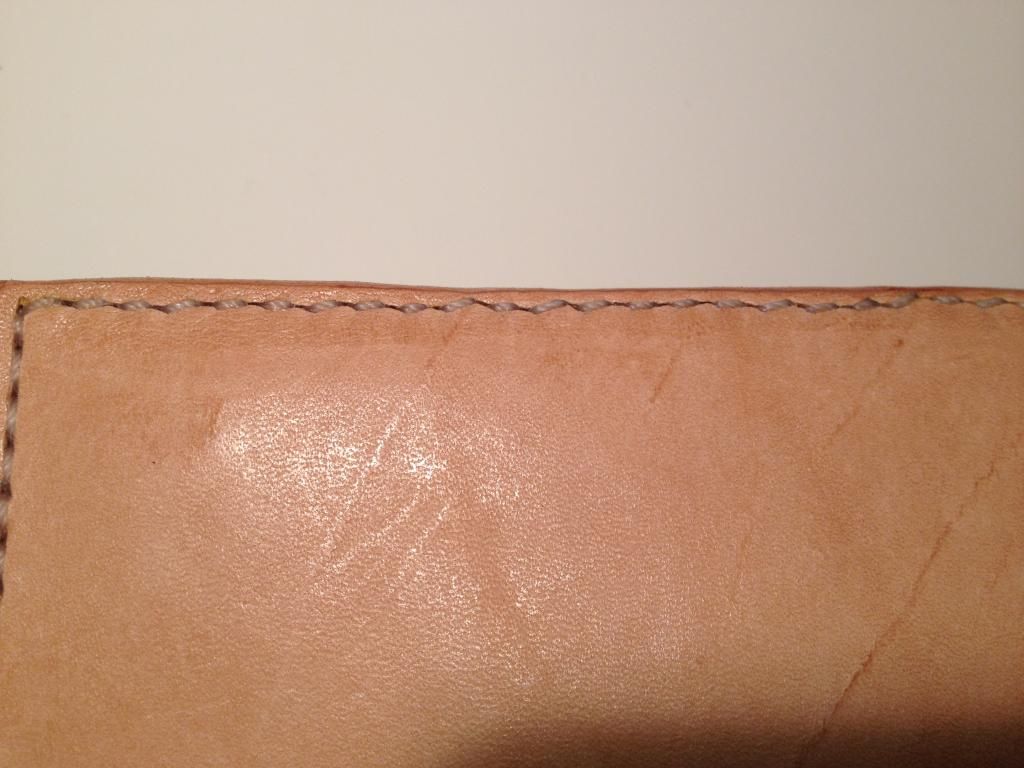

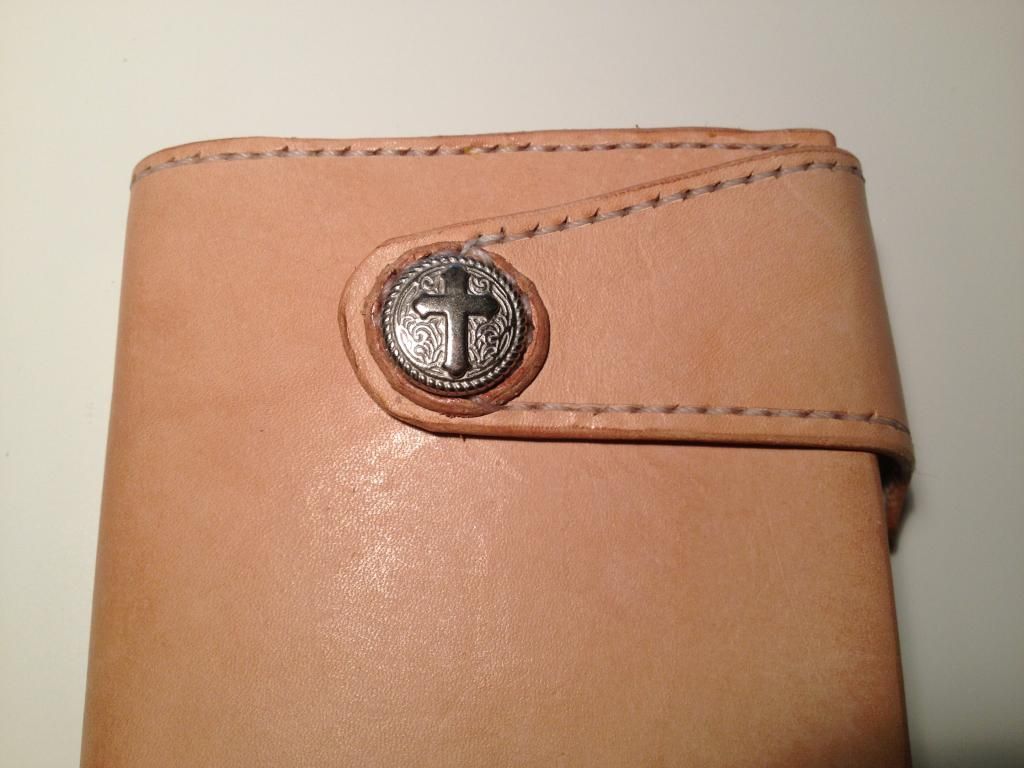

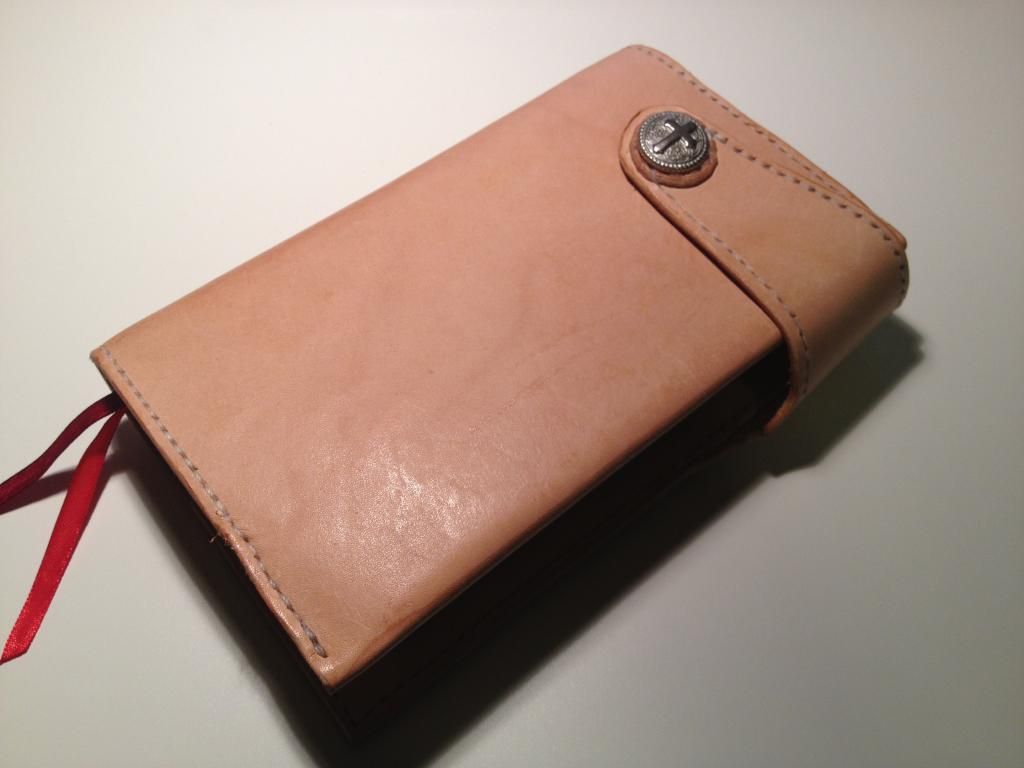

Quickly throw this together last night. I have a few problems:

1.Stitching holes don't lineup. I used an awl to poke holes for each stitch but I can't really control where the awl coming out on the back side. Do any of you guys know how I can get better?

2. Round edges don't look round. I used an xacto knife but I can't get the edges round enough to look professional. Can I get a nice round edge without a punch?

3. For cutting, I used an utility knife and a xacto knife. Both of them don't cut curves easy. Do I need to get a round knife or a Japanese leather knife for that job? I spent a lot $ on this hobby already so I don't want to spend a lot to get punches or those chisels (they aren't too expensive compare with a good knife, but can get pricey when I need different sizes).

Thanks for anyone who can give me some advice!

1

Post Your Leather Creations.

in superculture

Posted · Edited by Xin

I came up with this idea to make the wallet with minimum seams. But then, when I was browsing online, someone else already made it....