Leaderboard

Popular Content

Showing content with the highest reputation on 04/23/24 in all areas

-

3 points

-

2 points

-

2 points

-

2 points

-

2 points

-

@vIGGiou riou doh! Totally forgot the pic you posted... In case you don't like them, you can send them to me1 point

-

1 point

-

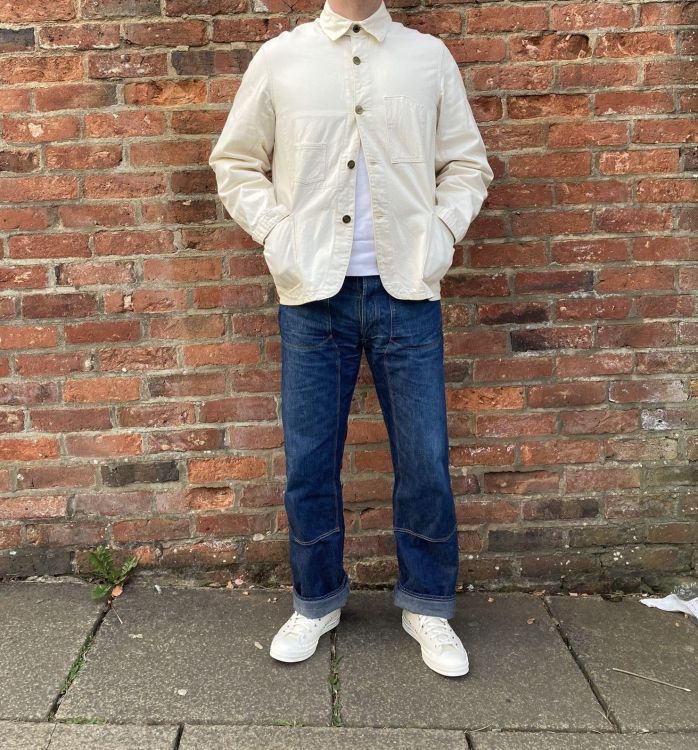

For me, I like the waist of my jeans to be around 33.5-34" right out the wash and stretch to around 36" to be comfortable and loose. I take a 34 in the 66's and 36 in the 47's (I find the waist to run smaller on these hence sizing up the tagged size.)1 point

-

Second pair are also Chippewa's. Western work boots in size 10 D. Very thick Vibram soles, made in USA, very rugged build. Very little wear, tons of life left in soles, and the uppers are practically perfect. Really love these boots but they are just too loose. Again, all reasonable offers considered.1 point

-

Hi Tilmann. Yes, of course they arrived. Picture I posted in start of April was my picture I did. They are Orrizonti era.... very nice piece. If RHT will do same evolution as my vintage Lee 101 Storm rider jacket, would be great. They are now vacuumed in queue and waiting for theirs time to be worn... Raw measurements of W34 is W 88cm Fr rise 31cm B rise 41cm Thigh in crotch 35 cm Knee 25cm Hem 23,5cm Inseam 89cm1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

On the topic of rocks matching clothes Tilley / Merz / Hollows / Roy / White’s1 point

-

1 point

-

1 point

-

1 point

-

I realise this is 3 years late but yes, I've got the lot 203's - I like em, pretty solid rendition of a WWII model jean, in their distinctive style. OD green herringbone twill pocket bags, no frills 5 pocket style, no rivets on the coin pocket, donut fly buttons - I like how "plain" these are. Mine are still very unworn as I went off them a while back and also had a bad do with hemming, now sorted and that has refreshed my interest, so getting some wear. Picked these up from The Vintage Showroom a few years ago when I was on a frenzied search for anything TWC, got these and a lovely chambray work shirt. This was after the brick and mortar store closing but they were still very obliging and kind over email, photographing all the pieces they had and posting some out to me.1 point